Mobile & PDA compatible

page

Our latest upgrade features the Cremer CF-830 Type II Tablet Counter Industrial

Electronic Design : We are experts in designing sensors to detect all sorts of products. This includes, but is not limited, to tablets and capsules. We also design PLC protocols to accurately count your products. PLC software includes Mitsubishi, TwinCAT and Allen Bradley. Our protocols can also be converted to common languages like C, C++, Pascal or assembler. We're currently working on a "Counter-In-A-Box" unit. This unit is for machine manufacturers that want to design a new tablet counter but do not want to worry about the electronic aspects. XIAC Australia designs sensors, emitters, sensor amplifier modules, vibrator control boards and can link everything together with a PLC and TouchScreen terminal.

Industrial

service & maintenance: We

service many manufacturing and packaging equipment around the Sydney

area. For example:

Machine

Upgrades: We

supply tailor

made electronics to

accurately count clear

gel capsules for

machines like King TB4 that have difficulties counting these

tablets. Your King TC8 or TC12 can also be upgraded with a container

reject station, special bottle sensors or anything else. Calibration

service: We calibrate King,

Swiftpack, Cremer and several label pre-counting equipment. Total Electronic

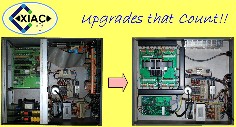

Makeovers (Retrofitting):

Pharmaceutical

Tablet counters like King TB5, TC8 or Cremer CF830 usually still

look like new even after more than 20 years. The problem is usually

not mechanically but electronically. The old electronic parts are no

longer supplied or have lead times over 8 weeks. To save production

down-time, we can deliver a package to completely strip all

electronics from these machines and replace them with

state-of-the-art modern technology electronics. This is much cheaper

than buying new machinery and more reliable than purchasing second

hand machinery. Machines that had a total electronic makeover will

last for another 15 to 20 years!

Click images to enlarge.

Cremer CF-830; King TC-8; King TC-12; King TB4; King TB5; Swiftpack SPC Upgrades

XIAC

is well known for solutions in industrial automation. We do

electronic repairs, electronic design, develop software,

improve/expand current solutions. Our main customers use

pharmaceutical tablet and capsule counting machinery.

King

TB-4, TB-5, King Dispensa

King

TC-8 Tablet counter (service, repair & upgrades)

King

TC-12 Tablet counter (service,

repair & upgrades)

Swiftpack

machines that have "SPARC SYSTEMS LTD" PSR25 (with and

without automatic gain control) (ELSEN25PSR)

sensors in the sensor head. PCS 2547/1 & PCS 2548 ISS 0. We

supply new “Dust-No-Problem!” sensors world-wide. New

sensors have 46dB electronic dust compensation and are exclusively

available through XIAC Australia.

Most

Cremer machinery including CF-830, CF-1230, CF-1220

Tronics

BLD-06 stepper motor controller/driver (labelling machine)

Lepel

induction sealer PSU

Disadvantages of

replacing your current tablet counter:

Shipping

& Installation costs of new equipment

Change

of floor plan due to different setup

Synchronization

problems with other equipment from same packaging line

Training

of staff due to unfamiliarity with new equipment

Obsolete

costly spare parts or wet-parts from old equipment

Compressed

air incompatibility (new equipment may require different air quality

specifications)

Electrical

incompatibility (50/60Hz problem; single-phase/ 3phase problem,

higher wattage, etc etc)

Calibration

and spare part costs (costs may be significantly higher for your new

equipment)

Advantages to

upgrade your current tablet counter with a XIAC retrofit:

Extend

life span of machine by another 15 to 20 years.

Current

machine can run until the date upgrade is ready to be installed.

Current

line setup will stay the same.

More

reliable than purchasing a used machine.

No

transportation and installation costs because current machine won’t

move.

Reduced

machine down-time because of brand new electronics.

More

advanced electronics for detection unit (when replacement required).

Cost

efficient to purchase spare parts locally.

New control

software allows for extra (not included) options like:

Container

reject station

Container

up-side-down detection

Container

index or other types of checking sensors

Increase

count accuracy and counting speed

Add

statistics functions (i.e. containers/minute, down time/week etc

etc)

Detection

of "Channel blockage", "product too long",

"Product double pulse" and "Product not separated"

to guarantee 100% count accuracy.

Detection

unit with electronic particle filter and automatic dust compensation

Accurate

counting of clear gel capsules

See

also our "Products"

and "Project"

on our main website.

www.xiac.com

www.xiac.com

services@xiac.com